Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

The past few months have seen the electric vehicle (EV) sector move from niche to mainstream, with global sales topping 10 million units in 2024—an increase of almost 30 % from the previous year. Reuters, Bloomberg, and the International Energy Agency all highlighted record sales in China, the United States, and Europe, driven by lower battery costs, expanding charging infrastructure, and ambitious climate regulations. While consumers are voting for zero‑emission cars, the components that make these vehicles possible are gaining their own spotlight. Among them, the humble gear motor, also known as a reducer motor, is emerging as a critical player in delivering the speed, efficiency, and reliability that EV manufacturers demand.

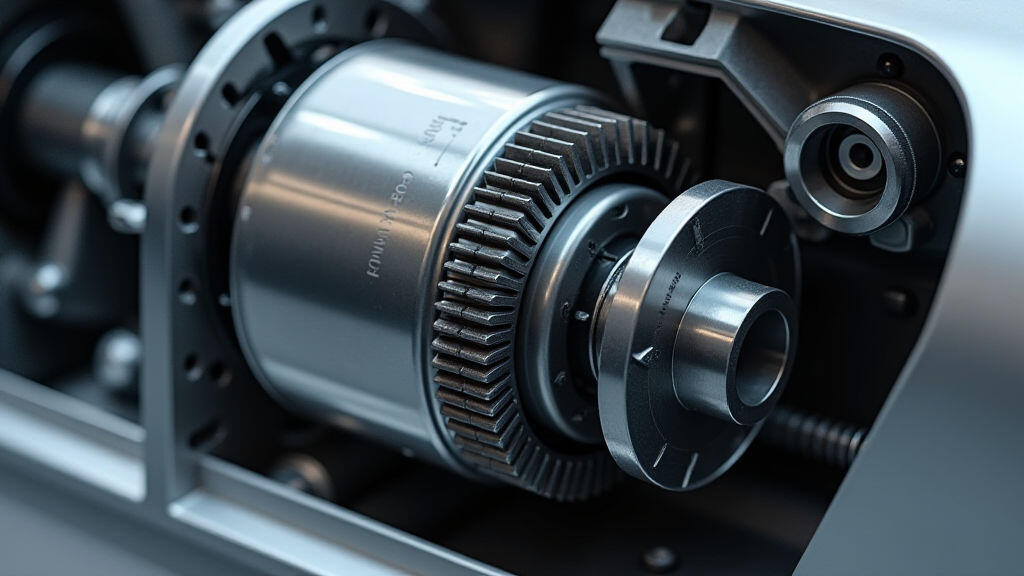

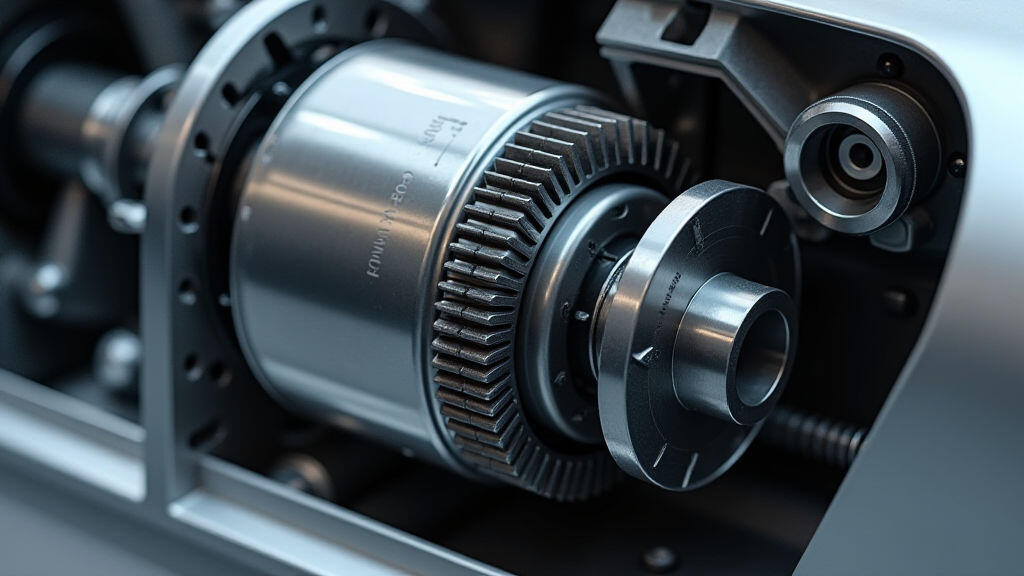

When people think of an electric car, they often picture a slick body and a powerful battery. But the heart of an EV is its drivetrain—the combination of motor, gears, and electronic controls that translate chemical energy into motion. Gear motors perform this translation by reducing the high speed, low torque output of an electric motor into the lower speed, higher torque needed by a vehicle’s wheels.

The key advantages of a gear motor in evailing with the rest appear in three areas:

According to a 2024 report from McKinsey, the average ratio of electric motor torque to vehicle torque in passenger cars is around 3:1. This means that a motor capable of 500 Nm of torque can be paired with a gear motor that multiplies that to 1,500–2,000 Nm at the axle while keeping the motor speed within its optimal operating band.

The surge in EV sales has created a direct appetite for high‑performance gear motors. OEMs such as Tesla, Volkswagen, and BYD are ramping up production, and each requires a steady stream of reliable gear reducers. In fact, Bloomberg NEF estimated that the global market for automotive gearboxes and gear motors will grow from $3.2 billion in 2023 to over $5.5 billion by 2028—an average annual growth of 13 %.

This growth is driven by several intersecting trends:

In the commercial sector, the pandemic accelerated adoption of vehicle electrification for sustainability and cost of fuel reduction. The same gear motor products that power passenger vehicles are now being used in electric buses and delivery vans, with an average life expectancy exceeding 20 million kilometers—demonstrating the durability that high‑quality gear motors bring.

Modern gear motors are not just scaled‑up versions of older designs. Engineers are pushing the boundaries by integrating additive manufacturing, advanced composite materials, and smart sensor technology. This has yielded motors that are 10 % lighter and 15 % more efficient than their predecessors.

Smart gear motors can now monitor load conditions in real time and adjust gear ratios via electronically commutated motors (ECMs). This dynamic adaptability is essential for vehicles with dual‑motor configurations, where real‑time torque distribution between front and rear wheels improves handling and energy recovery during braking.

The integration of AI‑based predictive maintenance with gear motors is another frontier. By analyzing vibration and temperature data, manufacturers can preemptively replace bearing assemblies before failure, reducing downtime for fleet operators and extending the life of each motor.

While mass production remains the bulk of gear motor manufacturing, the EV market’s rapid evolution demands more customization. Companies that can offer modular gear motor kits—allowing OEMs to swap gear ratios or torque ratings—are positioned as strategic partners.

Influential carmakers like BMW and Polestar are already working with suppliers to create “gear motor variants” that cater to different country regulations and driving environments. In colder climates, for instance, gear motors need to maintain performance at sub‑zero temperatures; Material scientists are selecting alloy compositions that preserve hardness and reduce thermal expansion differences.

In the enterprise sector, freight and logistics firms are seeking gear motors capable of carrying heavy loads (up to 50 kW) over varied terrain without compromising power density. Suppliers offering integrated cooling systems—ensuring the motor remains at optimal operating temperatures—can command premium pricing.

The electric vehicle market, which has captured headlines in 2024, is more than a trend—it’s a paradigm shift in how we produce, consume, and move energy. Behind the celebrated zero‑emission promises lies a network of precision components, with gear motors playing a central role. Their ability to convert high‑speed, low‑torque motor output into efficient, torque‑rich wheel rotation is fundamental to vehicle performance, range, and durability.

As global EV sales accelerate, the demand for high‑performance, lightweight, and smart gear motors is set to rise in tandem. Innovations in materials, sensor integration, and modular design are ensuring that gear motors will not just keep pace with, but actively shape, the future of mobility. For manufacturers, fleet operators, and consumers alike, gear motors remain a quiet but indispensable driver of the green transportation revolution.

Leave A Reply

Your email address will not be published. Required fiels are marked